Telescopic slide vs linear rail… How to choose?

The choice is not easy when you don’t know the specifics of each guide. Among the multitude of guides and slides in the CHAMBRELAN range, it is easy to get lost! All the more so as you can divert their use. In 4 points, we help you to find the right product for your installation!

Contents :

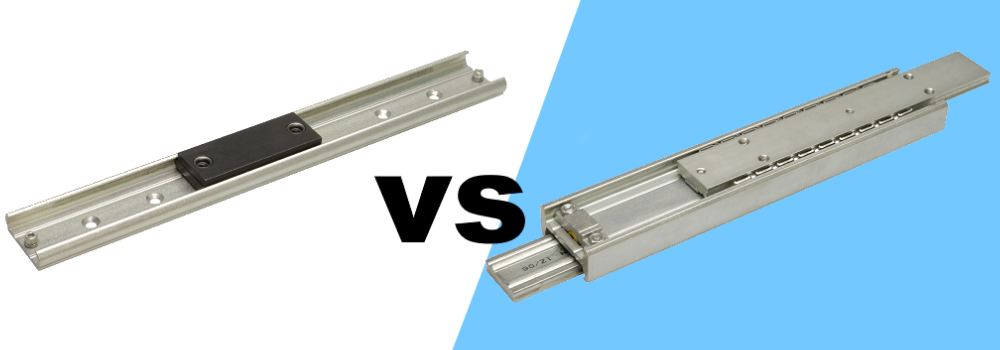

1- Telescopic slide or linear rail?

Let’s start with a reminder of what a telescopic slide and a linear railare:

A- Telescopic ball bearing slide:

Telescopic slide consists of elements that slide on ball bearings. It allows an EXTRACTION of a drawer for example, or of a tray or bins (battery for example).

If you have not yet had the opportunity to do so, we invite you to study our blog article “determining your telescopic slide in 5 steps”.

CHAMBRELAN ball bearing slides can support loads up to 1500 kilos! They are available in galvanised steel, anodised aluminium or stainless steel. We offer standard lengths from 150 mm up to 2 metres! They are available in two, three or four elements depending on the desired extension (partial extension, total extension or over-extension), up to 3 metres. They are resistant to temperatures from -20 to +80°C as standard, and up to 350°C on request. And of course, we offer many options (locks, treatments, customised lengths and developments, drilling plan…) to adapt our products to your needs!

-

-

- Some examples of applications

-

Ball bearing slides are present in all daily applications! You can find our slides :

B- Linear rail

In contrast to the ball bearing slide, the linear guide rail is not designed to extend, but to GUIDE in a linear way.

If you haven’t already done so, we advise you to consult our blog article ” Determine your linear guide rail in 4 steps “

It is composed of one or more runners (Ball bearing or roller runners) that slide inside the same rail. Generally proposed for any element that requires guiding from point A to point B. Available in standard lengths from 150 mm to 2 metres – they can be mounted end to end to achieve greater lengths, we offer rails in galvanised steel, anodised aluminium and stainless steel. Some of our runners can support up to 600 kilos! Ideal for simply moving ultra-heavy loads! The temperature of our rail ranges is similar to telescopic slides : -20° to +80°. Once again, according to your request we adapt our product! Do not hesitate to consult us!

-

-

- Some examples of applications:

-

You will be able to select our range of slides,

-

-

- for a sliding door in an industrial environment as well as for domestic use,

- for lift beds in the medical environment

- or even more surprisingly, for mounting in a horse-drawn van!

-

NB: we recommend that you always install our guides on major axis, as they have a better load resistance.

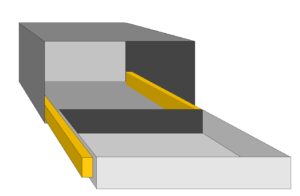

2 – Vertical mounting?

Your installation necessarily requires a vertical “up and down” type assembly? And you don’t know which of these two products would be the most suitable? Explanations !

A – Recommended guide rail

The linear guide rail is highly recommended! Indeed, the rail is designed to up and down a tray, door or protective cover without modification! Installed on major axis, the rail will support more load than minor axis. Therefore, you can consult and order any type of rail from our range without specifying the mounting direction. No additional manufacturing costs!

NB: our rails are delivered UNBORN, as it is easy to counter-drill them during assembly. However, we can drill them according to your plans, with average manufacturing times and a slight impact on the price.

B – Telescopic slide and additional stampings

If your project requires a vertical telescopic slide assembly, please let us know! Indeed, if you install ball bearing slides vertically, gravity will migrate the ball cages downwards, which will cause a loss of slide development. To remedy this, we can integrate a additional stampings on the slides. In this way, each element will open correctly one after the other without causing the ball cages to move out of alignment. This option will require a slight additional manufacturing and delivery time, and will result in a final surcharge.

C – Telescopic slides designed for vertical mounting :

Some of our telescopic slides can be installed vertically without modification. Thanks to the trapped balls inserted in the slide, the vertical guiding is done without a ball cage offset.

- A few examples of slides for this purpose:

ST38 :

This two-element ball bearing slide, in stainless steel, is 75% expanded. It is ideal for applications requiring a small surface area! Moreover it offers a smooth and silent sliding movement! Withstands medium loads and will support up to 85 kilos per pair for major axis! A galvanised steel version can be offered with similar dimensions and loads! Both versions can be mounted vertically without prior modifications!

E1400:

This steel slide is 100% totally developed. The major advantage of this slide is its robustness and its capacity to support loads of up to 130 kilos per pair for major axis in a minimum space! Polyamide ball rods facilitate the sliding of this “I” slide. It is also available in aluminium version D1422.

D402 :

This aluminium ball bearing slide is designed for medium loads and can support up to 30 kilos on major axis! It partially expands by about 75% of its folded length.

The D46is a lock out and disconnect version of this ball bearing slide. It facilitates the mounting or maintenance of the guided device.

D – Locking :

CHAMBRELAN locking is only available on telescopic slides and not on guide rails. For vertical mounting, this type of lock is not recommended (although it is technically feasible). Indeed, a simple latch may not be strong enough for vertical mounting. You can then design your own lock or consult our slam lock handle models (see ourarticle to choose the ideal slam lock handle for your installation)! For more security, CHAMBRELAN advises you to design an indexing system for your vertical mounting.

All you have to do is machine a flat plate drilled in 50mm steps and install it on each side of the door. So, if the user releases the control knob, the lock will engage at the next index

3 – Similarities and differences :

To sum up, if you still don’t know which product to choose between a telescopic slide and a guide rail according to your installation, here are the common points of these two products as well as their major differences:

A – Similarities

-

-

- Material: stainless steel, anodised aluminium or galvanised steel. We offer these three materials for each product.

- major axis mounting is recommended in contrast to minor axis mounting

- Standard lengths: 150 mm to 2 metres

- Operating temperature: -20° to +80° C

-

B – Differences

-

-

- Guide rail: designed for guiding a door, a protective cover or for vertical “up and down” use.

- Telescopic slide: designed for sliding drawers, trays or bins and for cantilevered support. Can be extended 75%, 100% or 150%.

- Rail can be installed alone, unlike the slide where we recommend mounting in pairs.

- For vertical mounting: guide rail as standard / telescopic slides as an option.

- Mechanical and integrated locks only on telescopic slides

-

4 – Options :

Please note that you can add the following options to our linear rails or telescopic slides on request:

-

-

- Specific treatment (hard anodising, high resistance against corrosion …)

- Stainless steel balls in place of steel balls

- Rail drilling on request and according to drawing

- Specific greases (edible grease, white grease, Teflon-free grease) or no grease

- Rail and slides made to measure (length and development)

- On some guide rails: installation of wipers to remove impurities in the raceway

- Locking: by lock (open/closed or open and closed) on telescopic slides

- SLAM Handle locks

- Double extension on some models of telescopic slides for a double extension of a drawer.

- lock out and disconect on certain models of telescopic slides to facilitate mounting or maintenance of on-board equipment.

- Hanging holes to optimise the time required for mounting slides and drawers or trays.

-