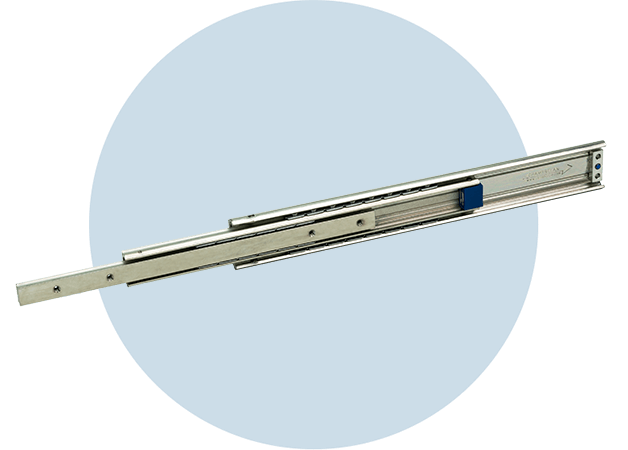

A range of solid and reliable drawer slides

Chambrelan specializes in the manufacture of drawer slides, and offers a complete range with several extensions to suit all your projects. Find out more about their features. If you have a question about the composition of our drawer slides (aluminum, stainless steel or steel) or the model best suited to your environment. Please do not hesitate to contact us so that our teams can answer your questions.

Filters

1. What is a drawer slide?

A Chambrelan drawer slide is composed of an assembly of ball bearing rails with ball cages and equipped with stops.

There are two types of drawer slides, the C-shaped and the I-shaped. Concerning the C-type, several parts are distinguished: the external part or the frame element, the drawer element or slider and the part allowing the extension of the slide called intermediate. The I-shaped slide has a fixed and mobile slider and a central moving metal element. This system makes it possible to extract heavy loads easily.

Other names associated to this guiding system: telescopic slide, ball bearing slide, sliding door slide…

2. What is the difference between a drawer slide and a sliding rail?

Unlike the drawer slide, the sliding track is made to move and guide an element lengthwise such as a door or a protective cover. The drawer slide, on the other hand, offers a great development for the sliding of drawers or trays.

The rail can be installed alone, unlike the slide, which must be installed in pairs. Vertical mounting is possible on the standard sliding rails but is an option on the slides. Mechanical locks are not available on sliding rails.

3. For what type of use are drawer slides designed?

The drawer slides are an asset in the industrial field. They facilitate the movement of heavy loads. They are adapted to several sectors such as :

● the medical sector for raising beds or for the fitting out of ambulances in order to extract the stretcher

● the railroad sector for access doors, battery boxes of wagons

● the industrial sector for the equipment of production machines or automatic food or banking machines

4. Drawer slides adapted to heavy loads and long lengths

Chambrelan, manufacturer of industrial slides and rails, offers more than 30 models of drawer slides with a load capacity ranging from a few kg to more than 1000 kg/3306.9366 pound. The folded lengths range from 150 mm/ 6 inch to 2 meters/32.8084 feet and the extensions from 100 mm to 3 meters/98.4252 feet.

5. Drawer slides with large extension capacities

Chambrelan, supplier of drawer slides, has designed three main families of slides:

● Partial extension drawer slides are composed of 2 elements, an external one and a slider. The extension is from 60 to 70% leaving a part of the mobile element inside the fixed part.

● Full extension drawer slides are composed of 3 elements. The extension is 100%, the three elements are superimposed which allows the third one to expand when the second one has reached its maximum length.

● The super extension drawer slides are composed of 4 elements. The development is 150% thanks to two superimposed intermediates.

These three models meet all the requirements and constraints of use in the technical and industrial sector.

6. Drawer slides easy to integrate and install, with many options

Double development, vertical assembly (guillotine type), locking… all the data necessary for the installation of Chambrelan drawer slides is available on this site. You will also find all the drawings, in different file formats for direct incorporation into your CAD/CAM application.

7. Linear guide systems in steel, aluminum or stainless steel

Chambrelan drawer slides are available in three types of materials: steel for most applications, aluminum known for its lightness or stainless steel for standard applications, corrosive environments or specific applications.

8. Surface treatments used

All Chambrelan drawer slides are delivered with an anti-corrosion treatment (white zinc plating for steel (RoHS) and colorless anodic oxidation for aluminum). The standard treatment is suitable for most applications. Different or additional treatments (e.g. hardness) can be applied according to the needs of the application or the environment.

9. Professional equipment with reduced maintenance

Lubricated at the factory with high-pressure bearing grease, Chambrelan drawer slides have an optimal service life and require very little maintenance. In case of special conditions (abrasiveness, high speed), it is recommended to plan a regular and systematic maintenance.

10. Standard or customized drawer slides

Chambrelan offers many models to meet your needs. In order to meet all your needs, the drawer slides can be made to measure. If you need solid and reliable custom-made rails, contact our teams, we will answer your request as soon as possible.